補上數位轉型的

關鍵拼圖

為什麼要在台灣推動 QIF?

台灣製造業以高品質與彈性供應鏈聞名,卻正面臨缺工、製程複雜化與國際客戶品質要求不斷提升的挑戰。多數企業已累積大量設計與量測數據,卻因資料格式不一致、系統彼此孤立,品質資訊無法串聯、追溯與重複利用,導致自動化受限、改善速度緩慢,AI 與智慧製造也難以真正落地。

QIF 作為國際通用的品質資訊標準,能統一設計、加工、量測與品管的資料語言,建立可追溯、可分析、可交換的品質資料基礎,讓既有系統與設備發揮更大價值。對台灣而言,推動 QIF 不只是導入一項新技術,而是補上數位轉型最關鍵、卻長期被忽略的底層工程,讓品質資料成為企業競爭力的核心資產,並順利銜接國�際供應鏈與未來的智慧製造發展。

台灣製造業的真實困境

🔻 品質資料分散在不同系統與格式

🔻 量測與檢驗高度依賴人工

🔻 問題難以追溯、改善速度慢

🔻 跨廠區與供應鏈難以協作

🔻 Digital Twin 無法真正落地

QIF 提供的關鍵解法

✅ 統一品質資訊格式,建立共同��語言

✅ 串聯設計、加工、量測與品管流程

✅ 建立完整可追溯的品質資料鏈

✅ 讓自動化與供應鏈協作成為可能

✅ 打造 智慧製造可用的資料基礎

_edited.jpg)

告別製造業的資訊孤島 — QIF:打造無縫接軌的數位品質流程

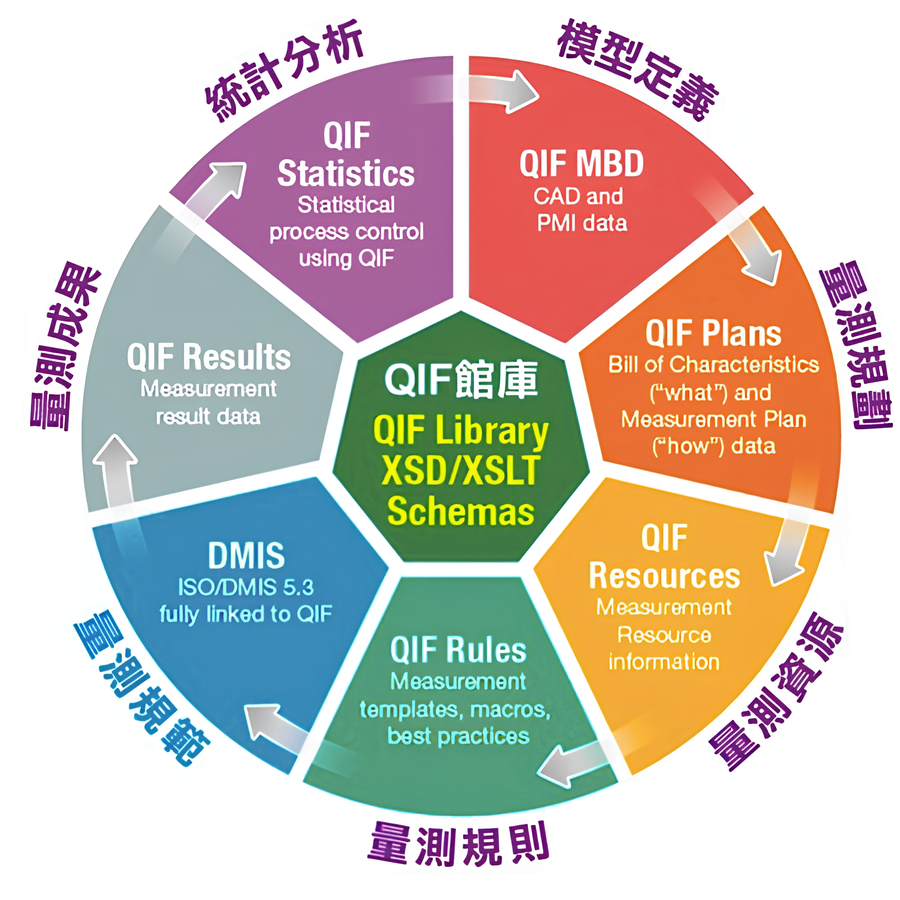

The official name of QIF is ISO 23952: 2020 Automation Systems and Integration – Quality Information Framework (QIF) – An Integrated Model for Manufacturing Quality Information; this standard was originally initiated by the US NIST, a quality standard developed by DMSC and audited by ANSI. , officially became the new ISO standard in July 2020. QIF is based on Model Based Definition (MBD) and XML architecture to establish a set of quality information framework for product production stages that connects design, manufacturing, measurement and quality management. Based on the principles of MBD, the definition of all information models is based on the definition of product design CAD models to define and track subsequent workflows; through the XML language, which is widely supported by various computer systems, obstacles in the transmission process of information models are eliminated. , to ensure that the MBD quality process can be completed smoothly. Simply put, the QIF MBD process not only ensures that product definition information is smoothly transmitted to each station in the product production process, but is also responsible for integrating and transmitting information from each station back to the units in need, which will be of great help to management and quality improvement.

The official name of QIF is ISO 23952: 2020 Automation Systems and Integration – Quality Information Framework (QIF) – An Integrated Model for Manufacturing Quality Information; this standard was originally initiated by the US NIST, a quality standard developed by DMSC and audited by ANSI. , officially became the new ISO standard in July 2020. QIF is based on Model Based Definition (MBD) and XML architecture to establish a set of quality information framework for product production stages that connects design, manufacturing, measurement and quality management. Based on the principles of MBD, the definition of all information models is based on the definition of product design CAD models to define and track subsequent workflows; through the XML language, which is widely supported by various computer systems, obstacles in the transmission process of information models are eliminated. , to ensure that the MBD quality process can be completed smoothly. Simply put, the QIF MBD process not only ensures that product definition information is smoothly transmitted to each station in the product production process, but is also responsible for integrating and transmitting information from each station back to the units in need, which will be of great help to management and quality improvement.

不再為製造資訊不相容而煩惱:導入QIF的效益

The QIF standard provides an information model framework, based on the MBD method, through which the quality work information of the product manufacturing process such as product models and definitions, measurement planning, statistical analysis and result recording are integrated. Through QIF's information framework, we can not only provide work instructions to subsequent stations, but also completely record complete information at each stage of the product quality process as a basis for quality improvement analysis and cross-department coordination discussions. Simply put, the QIF standard can bring the following benefits to enterprises: